Generate Bidding Reports

After the site survey is completed and uploaded to the tool, customer's source PLC5 or SLC 500 files are imported and I/O mapping is completed. The tool can generate six bidding reports. These reports enable you to get a clear picture of the source PLC5 or SLC 500 system's configuration details, inventory, external communications, sizing (the max limits of ControlEdge PLC versus current usage) and the new hardware needed to be procured by the customer to perform the migration.

These reports help users record their requirements and validate them – record existing inventory, hardware, communication protocols, size up the destination by knowing the number of used and spare channels (this situation comes in post-migration) and be informed of the hardware items to be used. The six reports are:

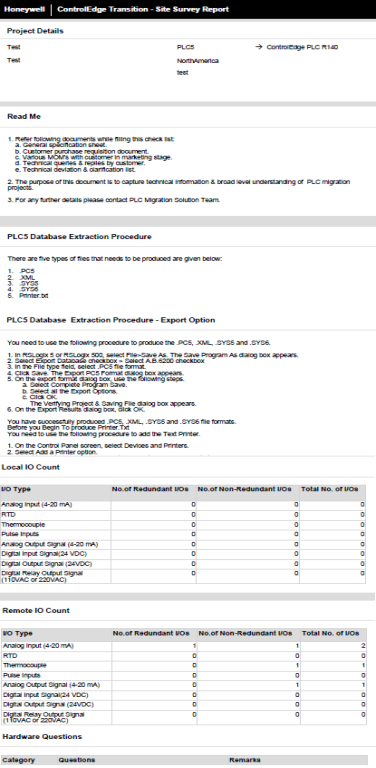

- Site Survey: This report consists of customer’s requirements and details of the source PLC5 or SLC 500 installation. It contains the list of required file formats from the source, the procedure to generate the source files required for migration, count of local and remote I/Os, and hardware PLC5 or SLC 500 information. This report serves to record and validate the requirements provided by the customer.

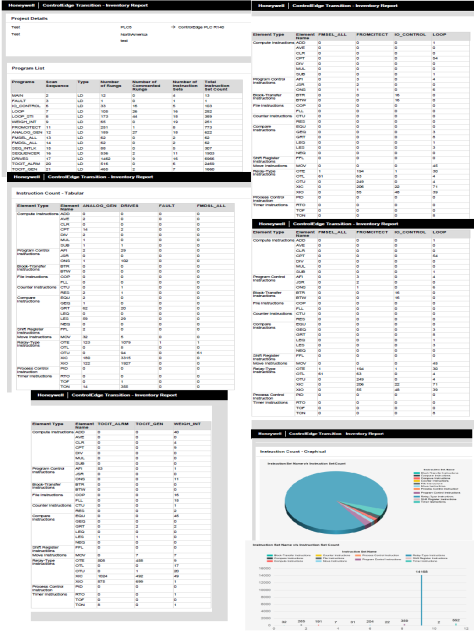

- Inventory: Consists of Program List and Instruction Count (in tabular and graphical formats). The Program list is a listing of all Programs in the source system and the Scan Sequence, Type, Number of Rung, Number of Instruction Sets, Total Instruction Set Count.

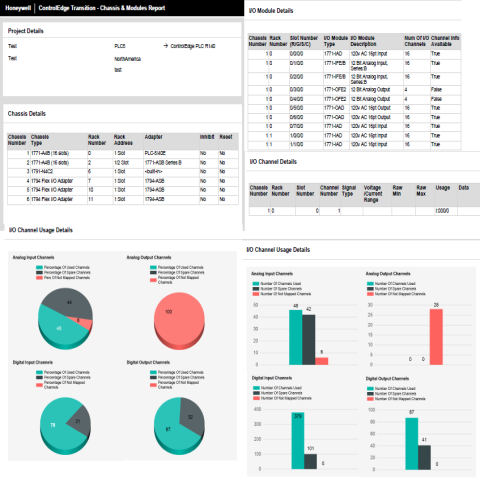

- Chassis & Modules: The report consists of information related to existing chassis, I/O modules and I/O Channel. The information is divided into tabular data consisting of Chassis details, I/O Module details, and I/O Channel details, and graphical representation of used and spare channels in percent and actual figures.

- External Communications: This report provides information about the source PLC5 or SLC 500 communication mechanism i.e., Serial, DH+, Ethernet, DeviceNet, ControlNet, and the Channel ID, Channel Name and Channel Type details for each mechanism, in addition to configuration details of each channel. This report also contains the communication addresses over which the source PLC5 or SLC 500 is communicating with external entities (another PLC, SCADA, or DCS).

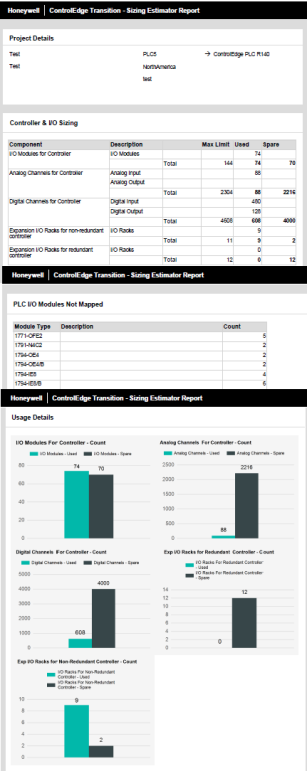

- Sizing: This report consists of information about ControlEdge system’s Controller and I/O Sizing & PLC I/O Modules Not Mapped. The Controller Sizing report gives in detail about the Component, Description, Max Limit, Used and Spare Components. These information are displayed in both tabular and graphical.

Furthermore, Instruction Count gives details of these elements: Compute Instructions, Program Control Instructions, Block-Transfer Instructions, File Instructions, Counter Instructions, Compare Instructions, Shift Register Instructions, Move Instructions, Relay-Type Instructions, Process Control Instructions and Timer Instructions in tabular form. The details on above mentioned element type are given with Element Name for each, FMSEL_ALL count, FROMCITECT count, I/O Control count and Loop. The instruction count details which was provided in tabular form is also provided in graphical form too.

In Chassis Details the Chassis Number, Chassis Type, Rack Number, Rack Address, Adaptor, Inhibit and Reset data is given.

In I/O Module Details the Chassis Number, Rack Number, Slot Number (R/G/S/C), I/O Module Type, I/O Module Description, Number of I/O Channels and Channel Information Availability is given.

In I/O Channel Detail the Channel Number, Rack Number, Slot Number, Channel Number, Signal Type, Voltage/Current Range, Raw Min, Raw Max, Usage and Data is given.

UIO channel count is not considered in the content of the report.

Note that I/O assignment is a mandatory pre-requisite for generating this report.

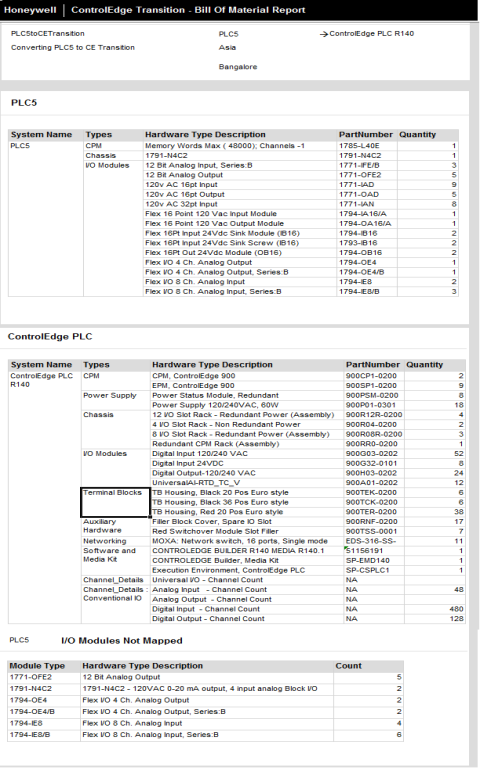

- Bill of Materials: This report consists of the hardware required by ControlEdge PLC - racks, CPMs, I/O modules, and power supplies - including their quantity and part numbers that are needed to be procured for the migration. A graphical representation of the quantities to be ordered is also provided.

Note that, I/O assignment is a mandatory pre-requisite for generating this report.

To generate a BOM report:

-

Select the Bill of Material check box under Bidding Reports. The BOM Reports Inputs pop up dialog box appears.

-

Provide inputs in the text boxes provided. Enter the options provided within brackets in the labels.

-

Click Generate.

To generate a report

-

Select the checkbox corresponding to the required report and click Generate.

-

Click on Select All checkbox and click Generate (to generate all bidding reports).

-

The selected reports is/are generated and displayed in a new browser window(s).

-

You have typical controls to navigate, zoom in/out, save and print the report.

-

You can also click

and select to save

the report in Microsoft Word, Mircosoft Excel or PDF formats.

and select to save

the report in Microsoft Word, Mircosoft Excel or PDF formats.

To generate a BOM report, you have additional steps to perform. These are described in the description of the BOM report in this document.

Before you begin to generate, you need to add the IP address in the browser (Google Chrome). The below steps will allow you to generate all your reports.

Procedure to enable browser to allow pop-ups

-

Click the Tools icon to view the settings.

-

Click Settings. The Settings page appears.

-

Type Content Settings in the search field.

-

Click Content Settings to view the Pop-ups tab.

-

Click Pop-ups tab to add the IP address.

-

On the Allow tab, click ADD. The Add a site pop-up appears.

-

Add the URL: https://www.migrationapps.honeywell.com/cetransition on the site tab.

-

Click ADD.